The industrial landscape of New Hampshire is gaining a new ally in the fight for cleaner air and process efficiency. TriboTech Solutions, a manufacturer of triboelectric bag leak detectors, has officially launched its operations right here in the Granite State.

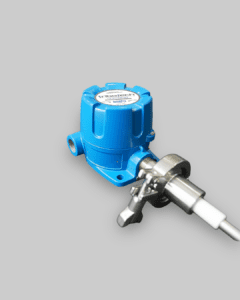

Designed for the demanding environments of industrial baghouses and material processing facilities, TriboTech’s sensors provide a dual-purpose solution: serving as both critical broken bag detectors for environmental compliance as well as process flow indicators for pneumatic conveying applications.

Deep Roots in Industry Expertise

While TriboTech Solutions is a new name in the local tech sector, it is built on a foundation of extensive experience. The company was founded by a veteran of the baghouse instrumentation field who spent over 16 years on the front lines of particulate monitoring applications.

After years of seeing facilities struggle with overly complex, erratic, or expensive monitoring systems, the founder set out to create a product that prioritized what plant managers and maintenance technicians value most: simplicity and reliability. While TriboTech manufactures locally, which supports the New Hampshire economy, it will deliver products both nationally and internationally.

How It Works: The Science of Triboelectricity

At the heart of every TriboTech sensor is the triboelectric effect (often referred to as particle impingement). As dust particles move through an air duct, they naturally carry a small electrostatic charge. When these particles pass near or strike the sensor’s probe, they induce a tiny electrical current, requiring extremely sensitive, stable circuitry.

Unlike meters that rely on light and can be easily prone to false signals by dust coated lenses, TriboTech’s sensors measure the actual physical interaction of particles. This makes them significantly more sensitive, allowing operators to detect a leaking bag long before a visible plume of dust ever leaves the stack.

And with an extremely wide dynamic input range, the same electronics can also be used for critical flow applications, reducing the number of different models and options the customer needs to order and keep on-hand.

Seamless Integration: The Power of 4-20mA

One of the standout features of the TriboTech line is its commitment to “no-fuss” integration. Each unit provides a standard loop-powered 4-20mA output. This continuous data signal allows for:

- Real-time Trending: Monitor dust levels 24/7 to predict when filters are nearing the end of their life.

- Easy Connectivity: The signal plugs directly into existing PLCs, SCADA systems, or data loggers without the need for proprietary converters.

- Simplified Wiring: As a loop-powered device, the sensor draws minimal power and transmits data over the same two wires, drastically reducing installation and on-going energy costs.

“Our goal was to strip away the unnecessary ‘bells and whistles’ that often lead to failure in the field,” says the TriboTech team. “We’ve delivered a rugged, New Hampshire-made tool that does exactly what it’s supposed to do: keep your plant running.”

For more information, visit tribopro.com.